The AGEM combustion of acetylene with oxygen produces very hot flame. This fire is so powerful it can use to smash all into little pieces and cutting the iron. The reaction between acetylene and oxygen is very hot, which is why it can be used for applications that need high temperatures. This is why acetylene and oxygen are one of the best resources for welding, cutting, as well as shaping metal materials.

But if you really wish to make the most out of your acetylene/oxygen AGEM mix combination, then you will need proper tools to do that in a safe manner. One of the most typical tools consists of a welding lantern that is made use of to blend and also manage the flow as well as quantity of acetylene and oxygen. You can create an appropriate type of flame suitable for the task you are being done by setting on the torch. Follow the instructions exactly, and be careful to avoid getting hurt.

Acetylene and oxygen are very versatile, allowing many different tasks to be performed using this process. Construction AGEM Manufacturing Automotive Repair As long as you have the appropriate skills and equipment, you can achieve the maximum output of acetylene from oxygen. For cutting through metal or soldering pipes to shaping sculptures, this efficient and precise combo can do the job right.

AGEM Acetylene with oxygen has numerous benefits. One of the major benefits of this is that it produces high heat so you can work with high efficiency. One other plus to acetylene working with oxygen is how much use you can get out of it — from heavy-duty welding all the way down to delicate soldering. Moreover, acetylene and oxygen are easily accessible and not very expensive like other available alternatives. In conclusion, using acetylene with oxygen means less stress and effort for you while promising impeccable flawless work.

While AGEM acetylene and oxygen can be a formidable combination, one should exercise caution while using it. Acetylene tanks should always be stored upright in a ventilated area, and never dropped or treated roughly. Protect your eyes and any exposed skin with goggles and gloves when using acetylene in combination with oxygen to prevent burns or eye injuries. Fire extinguisher next to you in case of emergency and never keep the fire unattended. Observing these safety tips will allow you to safely and efficiently use acetylene along with oxygen.

AGEM has been operating in Taiwan for over 25 Years. We have a deep R and D expertise in this area, and we can provide unique understanding in the areas of Speciality, Bulk, and Calibration Gases for six distinct regions.Taiwan - Kaohsiung City (Headquarters, R and D Center)India - Mumbai, Vadodara, Coimbatore, Pune, Bengaluru, DelhiChina - WuhanMiddle East - Dubai (UAE) and Kingdom of Saudi ArabiaUnited Kingdom - CambridgeThe gas solutions we offer comprise Technical Consulting. Assembling & Commissioning. Sample Testing. Packing & Shipping. Drawing Design. Manufacturing.

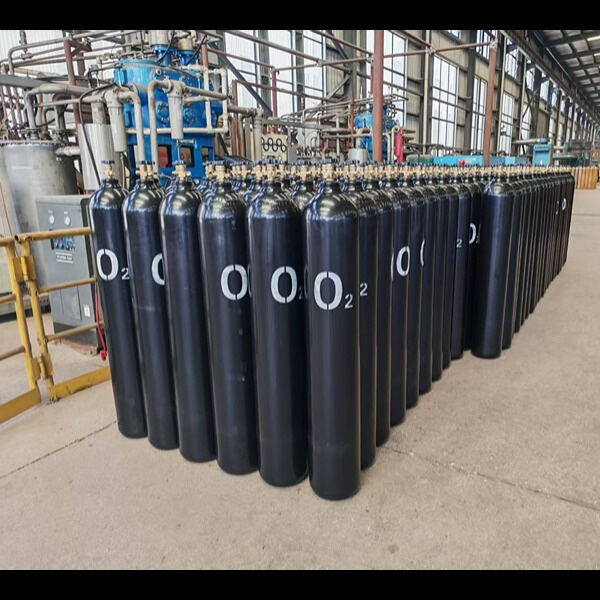

AGEM provides a range of cryogenic cylinders designed for super-cooled gasses and liquids like liquid oxygen and the argon. They can also hold nitrogen, carbon dioxide, and Nitrous. We utilize imported valves and equipment to ensure top performance. Use gas saving device and prioritize the use of tension gas in the gas phase space. Double safety valves are a safe method to ensure the safety of operation.We offer a variety of cryogenic cylinders that can accommodate liquids that are super-cooled and found in daily use.Full Volume: 80L/100L/175L/195L/210L/232L/410L/500L/1000LWork Pressure: 1.37MPa/2.3MPa/2.88MPa/3.45MPaThe Inner Tank Design Temperature is -196Shell Tank Design Temperature: -20oC~+50oCInsulation: Vacuum using Multi-layer WrappedStorage medium: LN2, LO2, LArLCO2, LNG

For Acetylene with oxygen, leaking gas is one of the major issues. Therefore, we perform leak tests more than five times to ensure quality. We have a complete manufacturing line and strict quality control along with a set of after-sales services. We ensure that our clients receive top quality products. We take pride in our commitment to excellence and customer service. Our skilled team is always available to assist you and ensure that you receive the best service with the highest level of satisfaction. What sets us apart is our availability 24 hours a day, seven days a week. service. We are available to assist you around the clock throughout the week.

AGEM is aware that different customers require different things with regard to special gases like calibration gases. We can provide tailored solutions that are tailored to our customers requirements. When you require a certain purity level, cylinder size, or packaging choice, AGEM can work with clients to customize their products to meet your specific requirements. This kind of customization will ensure that you receive the most suitable gas cylinders that can be calibrated for your particular application, while increasing overall effectiveness and performance. AGEM's product range is not only limited to calibration gases. The catalogue of AGEM includes Hydrocarbon Gases Halocarbons, Chemical Gases and Rare gases. You can be assured that AGEM will have the gas you require.