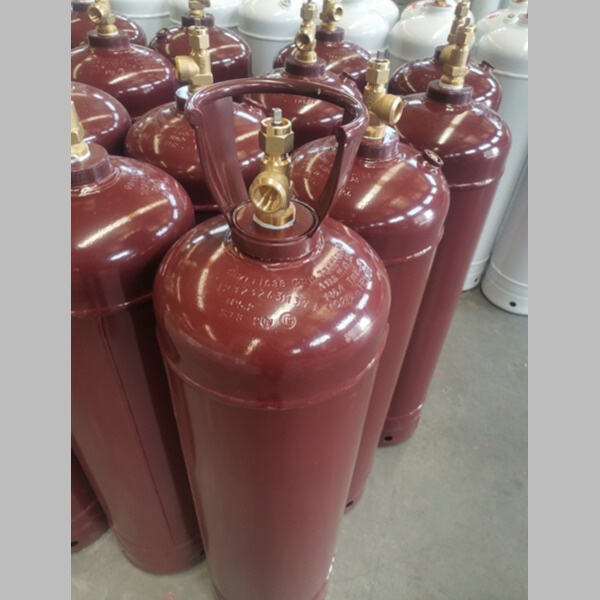

Acetylene is a very popular gas for welding and cutting. It is kept in a special bottle called the "acetylene bottle".

Welding and cutting are two of the most commonly used processes that either bind or remove materials. These tasks are critical in various industries, such as construction and manufacturing.

Since acetylene is a flammable gas, it requires great care during use and storage.

The advantages of using acetylene instead of other gases in welding and cutting are numerous. Perhaps the most critical of these is that acetylene burns at a significantly higher temperature than other gases.

Correct handling of the gas will yield plenty of savings with acetylene.

AGEM provides several cryogenic cylinders, which can handle commonly utilized super cooled gases and liquids, such as liquid oxygen, argon carbon dioxide, nitrogen, and nitrous oxide. We use imported valves and instruments to ensure maximum performance. Use gas saving device and prioritize the use of over tension gas in the gas phase space. Double safety valves are an effective method to ensure the safety of operation.We have a range of cryogenic cylinders designed to hold super-cooling liquids that are commonly found in daily use.Full Volume: 80L/100L/175L/195L/210L/232L/410L/500L/1000LWork Pressure: 1.37MPa/2.3MPa/2.88MPa/3.45MPaInner Tank Design Temperature: -196Shell Tank Design Temperature : -20oC+50oCInsulation: Vacuum with Multi-layer WrappedStored Medium: LCO2, LCO2, LCO2, LNG, LO2, L

AGEM has been operating in Taiwan for over 25 years. We have an extensive R and D experience in this area, and we are able to offer a distinct expertise in the fields of Speciality Bulk, calibration gases across six different regions.Taiwan - Kaohsiung City (Headquarters, R and D Center)India - Mumbai, Vadodara, Coimbatore, Pune, Bengaluru, DelhiChina - WuhanMiddle East - Dubai (UAE) & Kingdom of Saudi ArabiaUnited Kingdom - CambridgeOur gas services include Technical Consulting, Assembling & Commissioning, Sample Testing, Shipping and Packing, Drawing Design, Manufacturing.

For Bottle of acetylene, leaking gas is one of the biggest issues, which is why we conduct the leak testing more than five times in order to guarantee the quality. We have a fully-functional production line with a strict quality control, and a comprehensive system of after-sales services. This guarantees that our clients receive top quality products. We are proud of our dedication to excellence and customer service. Our highly skilled professionals are always available to assist you and ensure that your requirements are fulfilled. Our 24/7 service sets us apart. We are available to our customers all the time.

AGEM recognizes that various customers have unique requirements regarding specialty gases, such as calibration gas. We can provide tailored solutions that are tailored to our customers' specific needs. Whether you require a specific purity degree, size of cylinder, or packaging choice, AGEM can work with you to tailor their products according to your precise requirements. This degree of personalization will guarantee that you get the finest gas cylinders to calibrate your specific application, increasing overall efficiency and performance. The AGEM range of products is not just limited to calibration gas. Their catalogue includes Hydrocarbon gas, Chemical gases Halocarbons, Rare gases as well as a myriad of other gases used in research and industry. That means you can rely on AGEM to provide the exact gas you need.