Welding is a process in which metal can be joined best together with the help of heat. This technique is very, very old! In fact, ancient Egyptians were among the first welders in history. They made tools and weapons using a technique called forge welding. This step consisted in making the metal really warm until it could be hammered and joined together in one single piece.

Eventually later in the 19th century, more creative welding processes were invented. This changed the industry a lot through their use of electricity and gas. This helped workers to a great extent as it revolutionized welding. The most well-known and widely used combination of gas for welding today is a mix of oxygen and AGEM acetylene.

A significant benefit of working with oxygen and acetylene is the control. In other words, welders (administering welding) have been able to adjust the flame to be at the right temperature for a specific metal. AGEM oxygen and acetylene regulators are also able to create a larger or smaller flame, depending on their particular needs at that time.

The other biggest benefit of this combo gas is that it minimizes very minimal post-weld deleterious material known as slag. This is useful to ease the cleanup process after working with welding fumes. Additionally, due to the extreme intensity of the flame, welding can be accomplished faster as well, which in turn minimizes labor time and expense for workers and their organizations.

Besides cutting, these gases are utilized for heating metals so they can be bent and molded into different shapes. The practice of working with metals is referred to as metalworking and it plays a very crucial role in manufacturing. Metalworkers would struggle greatly to forge metal into the tools, parts and products we use day in and out without oxygen and acetylene.

Using oxygen and acetylene are very beneficial, but at the same time if safety is not taken into consideration it can be harmful. In such situations, it becomes very beneficial for a worker to wear goggles to protect his eyes and gloves to protect the hands. Similarly, the area in which welding is taking place has to be airy ie. well-ventilated as well. As the gases that are released during welding may be harmful to inhale.

Oxy-Acetylene are unique gases which serve a variety of purposes. Besides welding, they are also utilized for cutting and heating metal. Such flexibility has allowed workers to craft faster than at any previous point in history but also more efficiently. This straightforward gas mixture also gives an exceptionally hot flame that's easy to control. As a result, AGEM oxygen tank and acetylene makes welding and cutting significantly easier and faster to perform.

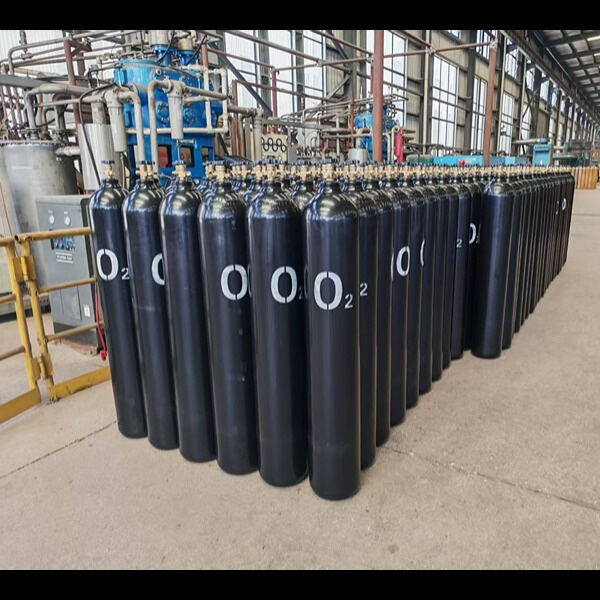

Leaks of Oxygen and acetylene is an extremely serious issue. We check for leaks over five times to ensure that the tank is of high quality. We have a complete production line and strict quality control and also a system of after-sales service. Our system ensures that customers get top-quality products. We pride ourselves on our dedication to high-quality and excellent customer service. Our team of skilled professionals is always ready to assist with your needs, making sure that all of your needs are met to your satisfaction. What makes us stand out is our 24/7 available service. We're there for you 24/7, every day of the week.

AGEM provides a variety of cryogenic cylinders, which can handle common super-cooled liquids and gases like liquid oxygen, argon carbon dioxide, nitrogen and Nitrous Oxide. We employ imported valves and equipment to ensure top performance. Gas saving devices are utilized and gas overpressure gas is given priority within the gas phase area. Double safety valve provides solid assurance for safe operation.We have a variety of cryogenic cylinders, which can house common super cooled liquids:Full Volume: 80L/100L/175L/195L/210L/232L/410L/500L/1000LWork Pressure: 1.37MPa/2.3MPa/2.88MPa/3.45MPaThe Inner Tank Design Temperature : (-196Shell Tank Design Temperature : 50oC+20oCInsulation: Multi-layer wrapped vacuum insulationStored Medium: LO2, LN2, LAr, LCO2, LNG

AGEM has been operating in Taiwan for more than 25 years. We have an extensive R and D expertise in this area and can offer unique expertise in the fields of Speciality, Bulk, and Calibration Gases across 6 different regions.Taiwan - Kaohsiung City (Headquarters, R and D Center)India - Mumbai, Vadodara, Coimbatore, Pune, Bengaluru, DelhiChina - WuhanMiddle East - Dubai (UAE) & Kingdom of Saudi ArabiaUnited Kingdom - CambridgeSolutions for gas offered by us comprise Technical Consulting. Assembling & Commissioning. Sample Testing. Packing & Shipping. Drawing Design. Manufacturing.

AGEM recognizes that every client has their own unique requirements with regard to specialty gases, such as calibration gases. This is why we offer customized solutions to fulfill the specific requirements of our customers. When you require a certain purity quantity, cylinder size or packaging choice, AGEM can work with you to customize their products to your exact specifications. This degree of personalization will ensure that you receive the finest calibration gas cylinders suitable for your needs, enhancing the overall effectiveness and performance. The AGEM range of products is not limited to calibration gases. The catalogue of AGEM covers Hydrocarbon Gases Halocarbons, Chemical Gases as well as Rare gases. You can be sure that AGEM has the gas you need.