One brand you might have heard of already is AGEM, which produces Argon CO2 cylinders. These are very essential and beneficial cylinders for their purpose of welding. These cylinders are used by welders to form a robust and secure connection between two pieces of metal. The Argon neutralizes the atmosphere of the weld area from air proximity by shielding the cylinder. This layer of protection is crucial as it prevents the metal from being damaged. Also, the CO2 gas helps develop and maintain a stable arc between the welding gun and metal, just like the AGEM's product called helium laser. That constant streak is necessary to ensure that the weld is sturdy and permanent.

Argon CO2 cylinders: Most of the professional welders prefer to use this type for their work. The top reason for this is these cylinders speak ease in the entire welding process. Welders weld better when it is easier to weld. If the gas is not right, for example it can turn into a hassle. However, such issues are rare with Argon CO2 cylinders, along with the wholesale helium tank supplied by AGEM. When welders steer clear of these obstacles, they can help save money and time in the end — improving their overall efficiency.

MIG welding needs using Argon CO2 cylinders outstandingly, thus these are very effective with this kind of welding, similar to the AGEM's product like specialty gas supplier. There is a kind of metal wire that through the MIG gun in the weld. The wire is then connected to a power source, which assists with the weld. This gas is called Argon, and it protects the metal inside the cylinder to avoid getting damaged. What it does is that it prevents oxidation, which is the process when air reacts to metal and may weaken it. The CO2 gas, on the other hand, aids in maintaining a stable welding arc. This also means that the entire weld is smooth and controlled. As a result it makes for an extremely robust weld. They are made to withstand heavy use which makes these types of welds perfect for many different types of projects.

Climbing the right size Argon CO2 cylinder for your welding job plays a great role, along with the nitrous oxide developed by AGEM. How big of a cylinder you need will depend on how much welding you plan to do and what size the pieces of metal are that you plan to weld. Opting for a larger cylinder is the better option if you think that you will be doing plenty of welding, or are working with bulkier pieces of metal. A big cylinder will fill more gas, so you never run out while working. This helps because you can continue to work uninterrupted,

Using an Argon CO2 cylinder can and does require some additional steps to ensure your welding is successful, just like the AGEM's product called tank argon. First, always ensure that the cylinder is secured tightly. That means that it should be somewhere safe so that way it does not tip over. Close the valve when you do not use the cylinder, too. This ensures the safety of gas and avoids accidents. Setting the proper flow rate and pressure values is also crucial during welding operations. Mismatched settings can give you poor output gown, however. And last but not least always wear your protective equipment. These are essential in keeping you safe from sparks and hot metal that can fly around while welding.

AGEM is aware that different customers require different things with regard to special gases like calibration gases. We can provide tailored solutions that are tailored to our customers requirements. When you require a certain purity level, cylinder size, or packaging choice, AGEM can work with clients to customize their products to meet your specific requirements. This kind of customization will ensure that you receive the most suitable gas cylinders that can be calibrated for your particular application, while increasing overall effectiveness and performance. AGEM's product range is not only limited to calibration gases. The catalogue of AGEM includes Hydrocarbon Gases Halocarbons, Chemical Gases and Rare gases. You can be assured that AGEM will have the gas you require.

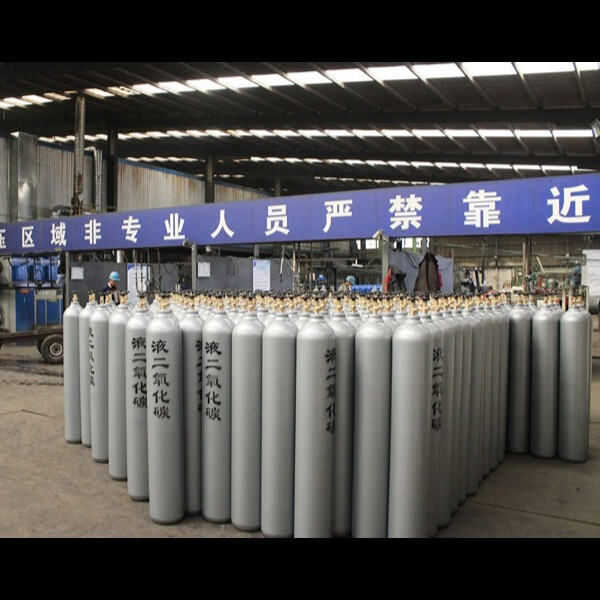

For Argon co2 cylinder, leaking gas is one of the major issues. Therefore, we perform leak tests more than five times to ensure quality. We have a complete manufacturing line and strict quality control along with a set of after-sales services. We ensure that our clients receive top quality products. We take pride in our commitment to excellence and customer service. Our skilled team is always available to assist you and ensure that you receive the best service with the highest level of satisfaction. What sets us apart is our availability 24 hours a day, seven days a week. service. We are available to assist you around the clock throughout the week.

AGEM is an Gas Manufacturing and R and D plant placed in Taiwan with more than 25 years of rich R and D expertise in this field, having an unparalleled expertise in the field of Speciality Electronic Bulk, Calibration and Speciality gases across the globe in 6 different regions:Taiwan - Kaohsiung City (Headquarters, R and D Center)India - Mumbai, Vadodara, Coimbatore, Pune, Bengaluru, DelhiChina - WuhanMiddle East - Dubai & Kingdom of Saudi ArabiaUnited Kingdom - CambridgeOur gas solutions consist of Technical Consulting, Assembling & Commissioning, Sample Testing, packing and shipping, Drawing Design, Manufacturing.

AGEM offers a wide range of cryogenic cylinders to cool super-cooling liquids and gases like liquid oxygen and the argon. They can also hold carbon dioxide, nitrogen and nitrous. We use imported valves and instruments to ensure maximum performance. Make use of gas saving devices and give priority to the use of over pressure gas in gas phase space. Double safety valves provide solid assurance for safe operation.We offer a wide range of cryogenic cylinders that can accommodate liquids that are super-cooled and utilized in daily life.Full Volume: 80L/100L/175L/195L/210L/232L/410L/500L/1000LWork Pressure: 1.37MPa/2.3MPa/2.88MPa/3.45MPaInner Tank Design Temperature : +196Shell Tank Design Temperature : 20oC+50oCInsulation: Vacuum with Multi-layer WrappedStored medium: LO2, LN2, LArLCO2, LNG